1410, PARKSON, 44-60 ZHONGSHAN ROAD, QINGDAO, CHINA

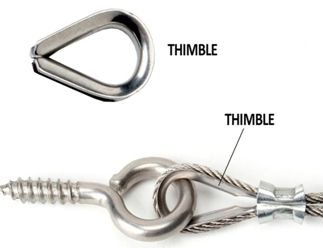

Thimble:

Thimbles are used to protect the eyes of cable, and rope slings from abrasion by providing a solid steel barrier between the fragile cable strands and the other rigging fitting used in the connection. Thimbles also prevent eye deformation or kinking by giving structure to the cable eye. After repeated high load use, wear and kinking can reduce the strength of the cable, and can lead to premature failure.

Thimbles are used to protect the eyes of cable, and rope slings from abrasion by providing a solid steel barrier between the fragile cable strands and the other rigging fitting used in the connection. Thimbles also prevent eye deformation or kinking by giving structure to the cable eye. After repeated high load use, wear and kinking can reduce the strength of the cable, and can lead to premature failure.

Type:

Light Duty

Light duty thimbles are typically used in static applications such as a permanent installation, a controlled environment, or in situations where they won’t experience much load. Light duty thimbles typically work best on traditional fiber rope because they can handle the same amount of load and rough handling as you would expect a fiber rope to take.

Light duty thimbles are typically used in static applications such as a permanent installation, a controlled environment, or in situations where they won’t experience much load. Light duty thimbles typically work best on traditional fiber rope because they can handle the same amount of load and rough handling as you would expect a fiber rope to take.

Heavy Duty

heavy duty thimbles have extended protective material around their edges, and a tendency to resist deformation in uncontrolled applications, they are commonly used in applications that will experience dynamic loading, or loads near or at the working load limit. Heavy duty thimbles are ideal for lifting, towing, and applications that will require the user to frequently connect and disconnect the thimble to other rigging components.

heavy duty thimbles have extended protective material around their edges, and a tendency to resist deformation in uncontrolled applications, they are commonly used in applications that will experience dynamic loading, or loads near or at the working load limit. Heavy duty thimbles are ideal for lifting, towing, and applications that will require the user to frequently connect and disconnect the thimble to other rigging components.

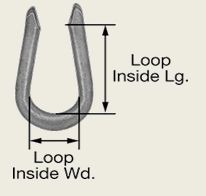

Open-End Light Duty Wire Rope Thimbles

Open ends allow more space to connect attachments than other thimbles. Made of  galvanized steel, these thimbles are corrosion resistant.

galvanized steel, these thimbles are corrosion resistant.

When choosing a thimble for your application, it’s important to consider what type of environment the thimble will be used in. E-Rigging offers thimbles that are made from Zinc Plated Steel, Hot Dipped Galvanized Steel, and Type 316 Stainless Steel.

Starting with the most corrosion resistant, stainless steel thimbles are best suited for being used in outdoor applications and are highly resistant to rust. Stainless Steel thimbles are also ideal for being used in or near saltwater environments where corrosion frequently occurs, and are the best choice when using stainless steel cable or chain.

shouldn’t affect the component’s performance.Our heavy duty, hot dipped galvanized thimbles come in at a lower cost than stainless steel, and are also suited for outdoor environments. While galvanized components are also ideal for outdoor use, galvanized components can exhibit signs of surface rust if the galvanized coating is worn off on the load bearing or contact areas of the component, this type of surface rust is normally worn off when loaded or used, and

Our light duty zinc plated thimbles can also be used outdoors, but it’s important to be aware that a zinc coating is thinner than a hot dipped galvanized coating, so the thimble may exhibit signs of rust earlier than a hot dipped galvanized thimble, this is especially true in environments where the thimble will be exposed to rain or snow, or in salt air or salt water environments.

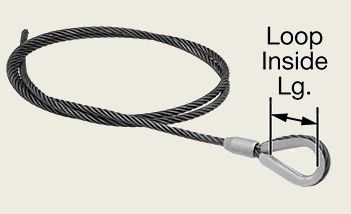

Steel Wire Rope with Reinforced Loop

With a reinforced loop, also known as a thimble eye, installed on one end, quickly attach a hook or a shackle to a wire rope. The thimble prevents fraying and the end is secured with a metal sleeve. The construction of this wire rope provides a good balance of abrasion resistance and flexibility. Individual wire strands are preformed to maintain their shape and prevent rope from unraveling when cut. Rope is lubricated to reduce wear.

and flexibility. Individual wire strands are preformed to maintain their shape and prevent rope from unraveling when cut. Rope is lubricated to reduce wear.

Galvanized steel lanyards are corrosion resistant.

18-8 stainless steel lanyards are more corrosion resistant than galvanized steel lanyards.

Thimbles can be used in conjunction with cable and rope to form rigging assemblies. The most important thing to consider when doing so, is making sure that the thimble is sized properly and securely fastened in the eye of the cable that is being used. If the thimble is too loose in the eye, it can fall out or rotate, and if it is undersized or grossly oversized, connections to other properly sized rigging fittings can become difficult.

and securely fastened in the eye of the cable that is being used. If the thimble is too loose in the eye, it can fall out or rotate, and if it is undersized or grossly oversized, connections to other properly sized rigging fittings can become difficult.

Thimbles are often used with other rigging components with a solid eye, and must be opened to do so. You can use a set of pliers to hold onto each side of the thimble, and with a twisting  motion, open the thimble so that the component can be inserted into the thimble and then return the thimble to its normal shape.

motion, open the thimble so that the component can be inserted into the thimble and then return the thimble to its normal shape.