1410, PARKSON, 44-60 ZHONGSHAN ROAD, QINGDAO, CHINA

What is a Turnbuckle?

A turnbuckle, stretching screw or bottlescrew is a device for adjusting the tension or length of ropes, cables, tie rods, and other tensioning systems. It normally consists of two threaded eye bolts, one screwed into each end of a small metal frame, one with a left-hand thread and the other with a right-hand thread. The tension can be adjusted by rotating the frame, which causes both eye bolts to be screwed in or out simultaneously, without twisting the eye bolts or attached cables.

Parts of a Turnbuckle

Body: the metal frame in the center of the device that joins the two threaded end fittings. The body itself is turned to adjust tension by extending and retracting the end fittings.

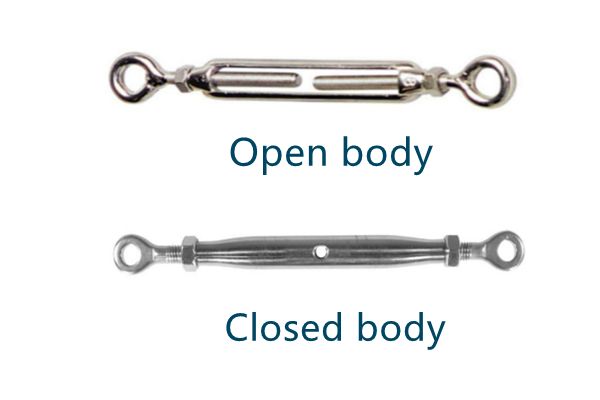

The body may be one of two types: closed or open. An open body turnbuckle is the more traditional type where the threads are visible through the body frame. Closed body turnbuckles—also known as pipe bodies—encase the threads in a closed frame to create a slimmer profile that fits in tighter spaces.

Nut: also referred to as a jam nut, the nut can be placed on the threads of the end fittings and tightened against the turnbuckle body to help prevent the device from loosening or unthreading.

End Fittings: these are the two connection points that screw into the opposite ends of the turnbuckle body. One end fitting is right-hand threaded while the other is left-hand threaded. This allows you to turn the body to adjust tension after installation without moving the end fittings.

There are three main types of end fittings that can be used together in any combination on either end of the turnbuckle:

Hook end – a hook end fitting is used to create temporary connections because they are easy to quickly connect and disconnect. They should never be used in connections where tension could unexpectedly release.

Jaw end – a jaw end fitting consists of a jaw and bolt secured together by a nut or a pin. These are used to connect to components that cannot be opened, such as an eye bolt.

Eye end – an eye end fitting is a closed loop that can be connected to a shackle or quick link.

Thread diameter: this is the diameter measurement of the threaded portion of the end fittings. The greater the thread diameter is, the greater the load-bearing capacity of the turnbuckle and vice versa.

Take-up length: this is the total length that the end fittings can screw into and out of the body to “take up” tension. Take-up length can be measured in terms of “opened” or “closed” end fittings: the end fittings are either fully extended or fully retracted.

Types of Turnbuckles

Turnbuckle types are, essentially, named for the combination of end fittings used in the device. The most common end fitting combinations are:

*Jaw and jaw

*Eye and jaw

*Eye and eye

*Hook and hook

*Hook and eye

As you might have guessed, an eye and eye turnbuckle has an eye end fitting on either end. Likewise, a hook and eye turnbuckle has a hook end fitting on one end and an eye end fitting on the other.

The combination of end fittings is determined by what the turnbuckles need to connect to and whether the solution is permanent or temporary.

A hook is used to attach to temporary connection points that may be frequently connected and disconnected. A jaw is used to attach to a connection point that does not open, such as an eye bolt or link. An eye is used to attach to a connection point that can open such as a shackle or quick link.

Common Uses for Turnbuckles

As mentioned above, turnbuckles can be used with a length of rope, cable, or other rigging assembly as a connection point to adjust slack and tension within the line.Turnbuckles can be used for something as simple as a fence or as complicated as a suspension bridge. Some industries that commonly use turnbuckles are:

Sports and entertainment – turnbuckles are used to act as a securement point and to create tension in the ropes surrounding a wrestling or boxing ring. You can’t see them, of course, since they are covered in soft material for the athletes’ safety!

Maritime transport – turnbuckles are commonly used to tension a ship’s lashing and rigging components.

Construction – turnbuckles are often used to provide tension support for suspension bridges, large buildings, and highway guardrail cable assemblies.

Aviation – cables and wires present within the construction of an aircraft—wings, flight control systems, etc—are tensioned by turnbuckles.

Installation of Turnbuckles

Proper installation of any type of rigging equipment is essential to maintaining safe and effective applications—turnbuckles are no different. Installing a turnbuckle is a rather straightforward process, here are the steps:

Unscrew end fittings from the body until completely extended to the full take-up length

Connect end fittings on either end to desired securement point

1) For an eye end fitting, simply loop it through whatever securement point it will be connected to (shackle, quick link, etc.)

2)For a hook end fitting, simply loop the hook around whatever point it will be [temporarily] secured to (thimble, shackle, etc.)

3)For a jaw end fitting, unscrew the bolt from the jaw, place the securement point between the clevis ears (thimble, eye bolt, etc), place the bolt through, and screw it shut.

3. Rotate the turnbuckle to move the end fittings closer together until you reach the desired tension in the rope or cable.

4. Tighten nuts—if you are using them—down to the body.

Like all other rigging devices, be sure to keep the Working Load Limit (WLL) in mind when installing your turnbuckles.

Top Materials for Turnbuckle Parts

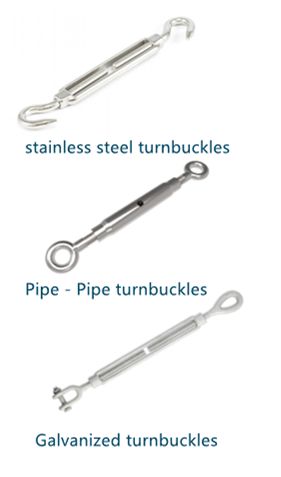

Stainless Steel - 316L stainless steel turnbuckles offer high corrosion resistance and durability with standard UNC threading to interchange hardware. They offer the highest resistance to high chloride or high moisture environments.

Pipe - Pipe turnbuckles are a version of stainless steel manufacturing. Unlike standard hardware, the body is enclosed in stainless steel pipe for cosmetic reasons (such as wire railings so that threads are not visible). It's UNC threaded so the fittings can be interchanged with standard turnbuckle fittings.

Galvanized - Galvanized turnbuckles use hot dip galvanized steel for durability, resistance to corrosives, and weather-resistance. Made for in-line or straight pull applications only.

Turnbuckle Markings / Identification

Each turnbuckle shall be durably marked by the manufacturer to show:

• Name or trademark of a manufacturer

• Size or rated load

Turnbuckle Inspection and Removal From Service Criteria

During the course of an inspection, remove the turnbuckle from service if any of the conditions listed:

• Missing or illegible identification

• Indications of heat damage, including weld spatter or arc strikes

• Excessive pitting or corrosion

• Bent, twisted, distorted, stretched, elongated, cracked, or broken load-bearing components

• Excessive nicks or gouges

• A 10% reduction of the original or catalog dimension at any point

• Excessive thread damage or wear

• Evidence of unauthorized welding or modification

• Other conditions, including visible damage, that cause doubt as to continued use

Find more information about wire rope clips :

https://www.huahanmachinery.com/turnbuckles01.html