1410, PARKSON, 44-60 ZHONGSHAN ROAD, QINGDAO, CHINA

Beam clamps are indispensable connecting components in steel structure construction. They are primarily used to quickly and securely connect steel beams or I-beams together, and are widely used in steel structure buildings, bridges, industrial plants, and other fields. This article will elaborate on the structural features, working principles, and key points of installation and usage of beam clamps, helping construction personnel better master the skills of using this product and ensure construction safety and quality.

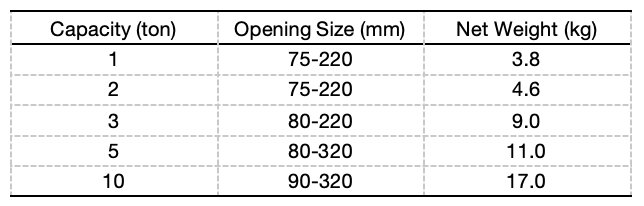

Specifications and Parameters of Beam Clamps

When selecting and using beam clamps, it's essential to understand their specifications and parameters. Beam clamps usually come in multiple models to accommodate steel beams of different sizes. The main specifications are as follows:

As the load capacity increases, the opening size and self-weight of the beam clamp also increase accordingly. The opening size refers to the thickness range of the steel beam flange that the beam clamp can grip. When using, it is necessary to select the model with an opening range matching the actual size of the steel beam.

The load capacity reflects the strength grade of the beam clamp. The greater the capacity, the thicker and heavier the steel beam it can connect, and the more applications it is suitable for. Generally speaking, beam clamps with a capacity of 1-3 tons are mostly used for light steel structures, while those with a capacity of 5 tons or more are mostly used for heavy steel structures. In addition to size and load capacity, the material of the beam clamp is also a factor to consider.

We specialize in providing customized beam clamp solutions to meet the diverse needs of our clients. With our extensive expertise and state-of-the-art manufacturing facilities, we can produce beam clamps in a wide range of sizes, load capacities, colors and materials.

Professional Advice on Selecting and Using Beam Clamps

1. Size Selection: The size of the beam clamp must match the width of the steel beam flange. Common beam clamp sizes include BC13, BC17, BC24, etc., which are suitable for I-beams with flange widths of 100-130mm, 130-170mm, and 180-240mm, respectively.

2. Material Selection: Beam clamps are mostly made of Q235 steel and are hot-dip galvanized for good strength and corrosion resistance. Some manufacturers also offer stainless steel options, which can be selected according to the usage environment.

3. Installation Position: Beam clamps are usually installed at the 1/4 span of the steel beam flange to achieve the best force balance. The spacing between two beam clamps should not be too large, generally controlled within 500-1000mm.

4. Bolt Tightening: The bolts of the beam clamp need to be tightened to the specified torque value, generally 150-250N·m. A torque wrench can be used to check and ensure reliable clamping force.

5. Regular Inspection: During use, the tightness of the beam clamp should be regularly checked and problems should be dealt with in a timely manner. At the same time, pay attention to corrosion prevention and perform rust removal and touch-up painting when necessary.

The quality of beam clamps directly affects the safety and efficiency of steel structure construction. Therefore, construction companies must choose reputable and high-quality manufacturers when purchasing. The beam clamps produced by our company are made of high-quality steel, with excellent manufacturing craftsmanship and reliable performance, which are widely praised by customers.

If you need to learn more professional knowledge about beam clamps, please visit our website.

https://www.huahanmachinery.com/lifter03.html

We have a professional technical team that regularly publishes relevant knowledge articles and product updates to help take your steel structure construction projects to the next level!